Buehler Walker: Precision Surface Grinders For Advanced Manufacturing Applications

Editor's Notes: Buehler Walker: Precision Surface Grinders For Advanced Manufacturing Applications has published today date. It conveys that you can purchase advanced manufacturing applications for precision surface grinders by Buehler Walker.

After doing analysis and digging information, we made Buehler Walker: Precision Surface Grinders For Advanced Manufacturing Applications guide to help target audience make the right decision.

Buehler Introduces IsoMet™ High Speed - An Advanced Precision Cutter - Source www.prnewswire.com

Key differences or Key takeways

FAQ

This FAQ section provides comprehensive answers to frequently asked questions regarding Buehler Walker's high-precision surface grinders, designed for advanced manufacturing applications.

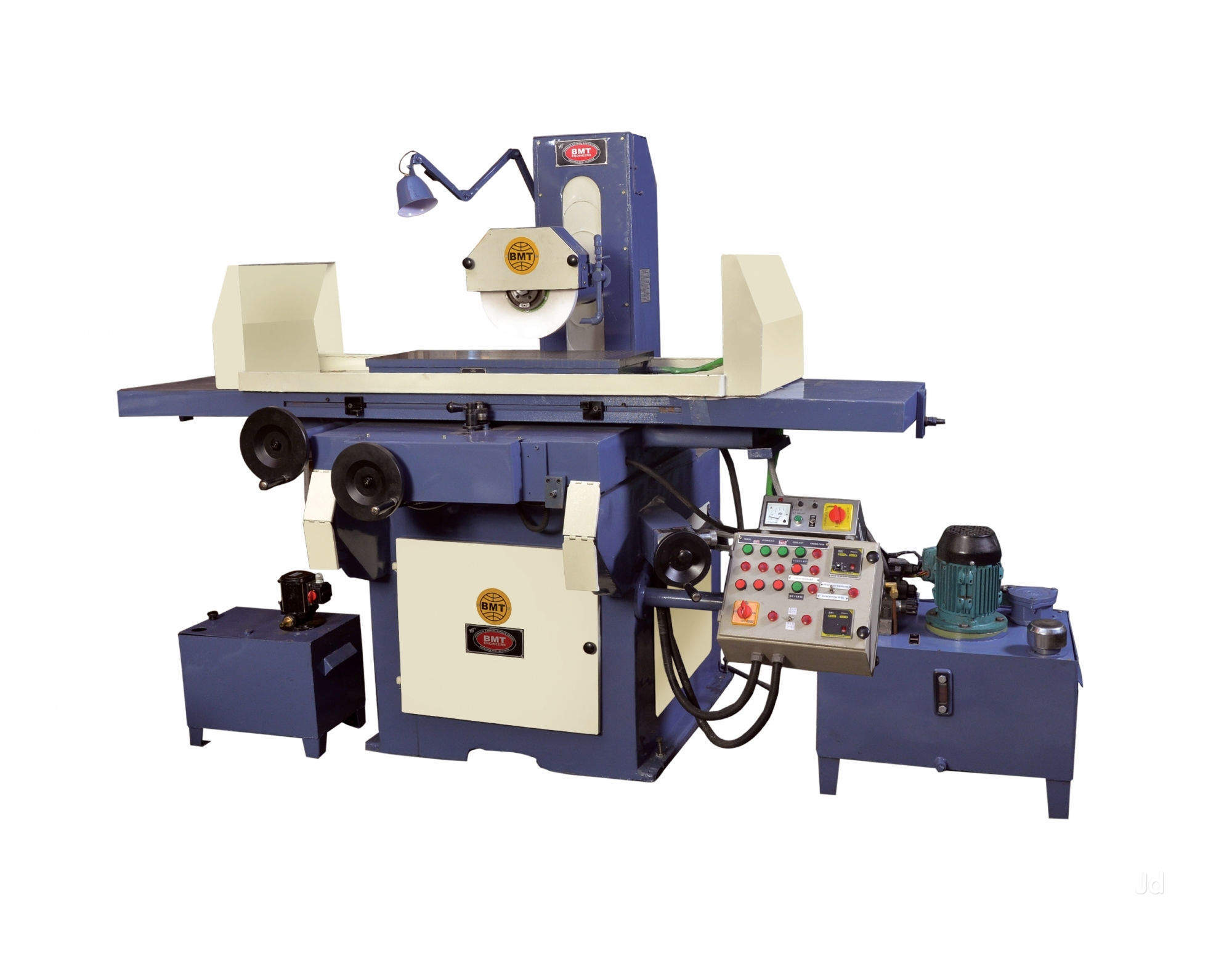

Buy Online Precision Surface Grinders, Manufacturer,Supplier and Exporter - Source www.bmtsurfacegrinder.com

Question 1: What sets Buehler Walker's surface grinders apart from competitors?

Buehler Walker's surface grinders are renowned for their exceptional precision, repeatability, and reliability. Advanced engineering and cutting-edge technology ensure superior surface finishes, minimal vibration, and extended machine life.

Question 2: How can these grinders enhance manufacturing efficiency?

Buehler Walker's surface grinders optimize manufacturing processes by reducing cycle times, minimizing rework, and increasing productivity. Their advanced controls and automation features enable seamless operation and reduced downtime.

Question 3: What materials are compatible with these grinders?

Buehler Walker's surface grinders are versatile and can handle a wide range of materials, including metals, ceramics, composites, and glass. They can grind complex shapes and intricate geometries with precision and accuracy.

Question 4: How do these grinders contribute to quality control?

Buehler Walker's surface grinders play a crucial role in quality control by producing surfaces with precise dimensions, flatness, and surface roughness. They ensure compliance with industry standards and customer specifications.

Question 5: What maintenance requirements should be considered?

Regular maintenance is essential for optimal performance and longevity of Buehler Walker's surface grinders. Preventive maintenance schedules and periodic inspections help minimize downtime, extend equipment life, and maintain peak grinding capabilities.

Question 6: Where can I get support for Buehler Walker's surface grinders?

Buehler Walker provides comprehensive support through its global network of technical experts and distributors. They offer troubleshooting assistance, spare parts availability, and operator training to ensure uninterrupted operation and maximize machine utilization.

In summary, Buehler Walker's precision surface grinders offer exceptional performance, reliability, and versatility for advanced manufacturing applications. They enhance efficiency, improve quality control, and minimize maintenance requirements, while providing unparalleled support to ensure customer satisfaction.

To explore further information and discover how Buehler Walker's surface grinders can revolutionize your manufacturing processes, visit the company's official website.

Tips

Visit Buehler Walker: Precision Surface Grinders For Advanced Manufacturing Applications to delve deeper into these tips.

Buy Online Precision Surface Grinders, Manufacturer,Supplier and Exporter - Source www.bmtsurfacegrinder.com

Tip 1: Use the right coolant. The type of coolant used can have a significant impact on the quality of the grind. For example, water-based coolants can help to prevent rust and staining, while oil-based coolants can provide better lubrication and cooling.

Tip 2: Choose the right grinding wheel. The type of grinding wheel used will also affect the quality of the grind. For example, diamond wheels are very hard and can be used to grind hard materials, while aluminum oxide wheels are softer and can be used to grind softer materials.

Tip 3: Use the correct grinding speed. The grinding speed will also affect the quality of the grind. For example, a faster grinding speed can be used to remove material quickly, while a slower grinding speed can be used to produce a finer finish.

Tip 4: Use the correct grinding pressure. The grinding pressure will also affect the quality of the grind. For example, a higher grinding pressure can be used to remove material quickly, while a lower grinding pressure can be used to produce a finer finish.

Tip 5: Use the correct grinding technique. The grinding technique used will also affect the quality of the grind. For example, a straight grinding stroke can be used to produce a flat surface, while a circular grinding stroke can be used to produce a curved surface.

Summary: By following these tips, you can improve the quality of your grinding operations. By using the right coolant, grinding wheel, grinding speed, grinding pressure, and grinding technique, you can achieve the desired results for your specific application.

For more information on precision surface grinders, visit Buehler Walker: Precision Surface Grinders For Advanced Manufacturing Applications.

Buehler Walker: Precision Surface Grinders For Advanced Manufacturing Applications

In advanced manufacturing, precision surface grinders from Buehler Walker play a crucial role in shaping and finishing surfaces. These grinders are often used in industries such as aerospace, automotive, medical, and electronics, where high-precision and surface quality are paramount. This article delves into six key aspects that make Buehler Walker precision surface grinders indispensable for advanced manufacturing applications.

1990 MITSUI MSG-200MH Horizontal Surface Grinders | Myers Technology Co - Source myerstc.com

- High Precision: Buehler Walker grinders deliver exceptional precision with advanced control systems and rigid construction, ensuring consistent and accurate results.

- Surface Quality: These grinders produce surfaces with exceptional finish quality, minimizing defects and reducing the need for subsequent finishing operations.

- Productivity: Buehler Walker grinders optimize productivity through fast cycle times, automated loading and unloading systems, and user-friendly interfaces.

- Versatility: They can handle a wide range of materials, from metals to ceramics, and can be configured for various applications such as flat, cylindrical, and angle grinding.

- Reliability: Built with durable components and backed by comprehensive support, Buehler Walker grinders ensure years of reliable operation.

- Innovation: Buehler Walker continuously develops innovative technologies, such as laser-guided dressing and adaptive control, to enhance grinder performance and efficiency.

In summary, Buehler Walker precision surface grinders offer exceptional precision, surface quality, productivity, versatility, reliability, and innovation. They are an essential component in advanced manufacturing applications where high-quality surfaces and efficiency are critical. These grinders enable manufacturers to produce complex parts with tight tolerances, reduce production time, and meet the demanding requirements of modern manufacturing.

DSC_0082.JPG of surface grinder precision Vise 2 5 max opening 17225 - Source yabe.chudov.com

Buehler Walker: Precision Surface Grinders For Advanced Manufacturing Applications

Buehler Walker's precision surface grinders are engineered to meet the demanding requirements of advanced manufacturing applications. These machines are designed for high-precision grinding of flat surfaces, and they feature a number of advanced features that ensure accuracy, repeatability, and productivity.

Walker Precision Engineering | Providing innovative manufacturing - Source walkerprecision.com

One of the most important features of Buehler Walker's precision surface grinders is their rigid construction. The machines are built with a heavy-duty cast iron frame that provides a stable platform for grinding. This rigidity helps to minimize vibration and ensures that the machine can maintain its accuracy over long periods of time.

Another important feature of Buehler Walker's precision surface grinders is their high-quality spindle. The spindle is made of hardened and ground steel, and it is supported by precision bearings. This design ensures that the spindle can rotate smoothly and accurately, even under heavy loads.

Buehler Walker's precision surface grinders are also equipped with a number of advanced features that make them easy to use and maintain. These features include a digital readout that displays the position of the grinding wheel, a programmable controller that allows the user to set up and store grinding programs, and a coolant system that helps to keep the grinding wheel cool and lubricated.

Buehler Walker's precision surface grinders are used in a wide variety of applications, including the manufacture of precision components, medical devices, and cutting tools. These machines are known for their accuracy, repeatability, and productivity, and they are an essential part of many advanced manufacturing operations.

Here is a table summarizing the key features and benefits of Buehler Walker's precision surface grinders:

| Feature | Benefit |

|---|---|

| Rigid construction | Minimizes vibration and ensures accuracy |

| High-quality spindle | Ensures smooth and accurate rotation |

| Advanced features | Makes the machines easy to use and maintain |

Conclusion

Buehler Walker's precision surface grinders are an essential part of many advanced manufacturing operations. These machines are known for their accuracy, repeatability, and productivity, and they are used to manufacture a wide variety of precision components, medical devices, and cutting tools.

As the manufacturing industry continues to evolve, Buehler Walker is committed to providing its customers with the latest and greatest in precision surface grinding technology. The company's engineers are constantly working to develop new and innovative features that will improve the performance and productivity of its machines.

If you are looking for a precision surface grinder that can meet the demands of your advanced manufacturing application, then Buehler Walker is the name you can trust.